Furniture Fastening

Different furniture requires different kinds of fasteners that would ensure smooth use of the pieces. And these fasteners need to be highly durable and well-welded so that they can stand up to your expectations. And at CNRL, we have a large inventory of standard furniture fasteners that will surely offer you a wide range of products to choose from.

Whether you are a furniture manufacturer or a furniture fastener supplier, you will indeed find what you need at CNRL. Our team of experts would also cater to your custom furniture fastener needs, exceeding your expectations in both design and quality!

1

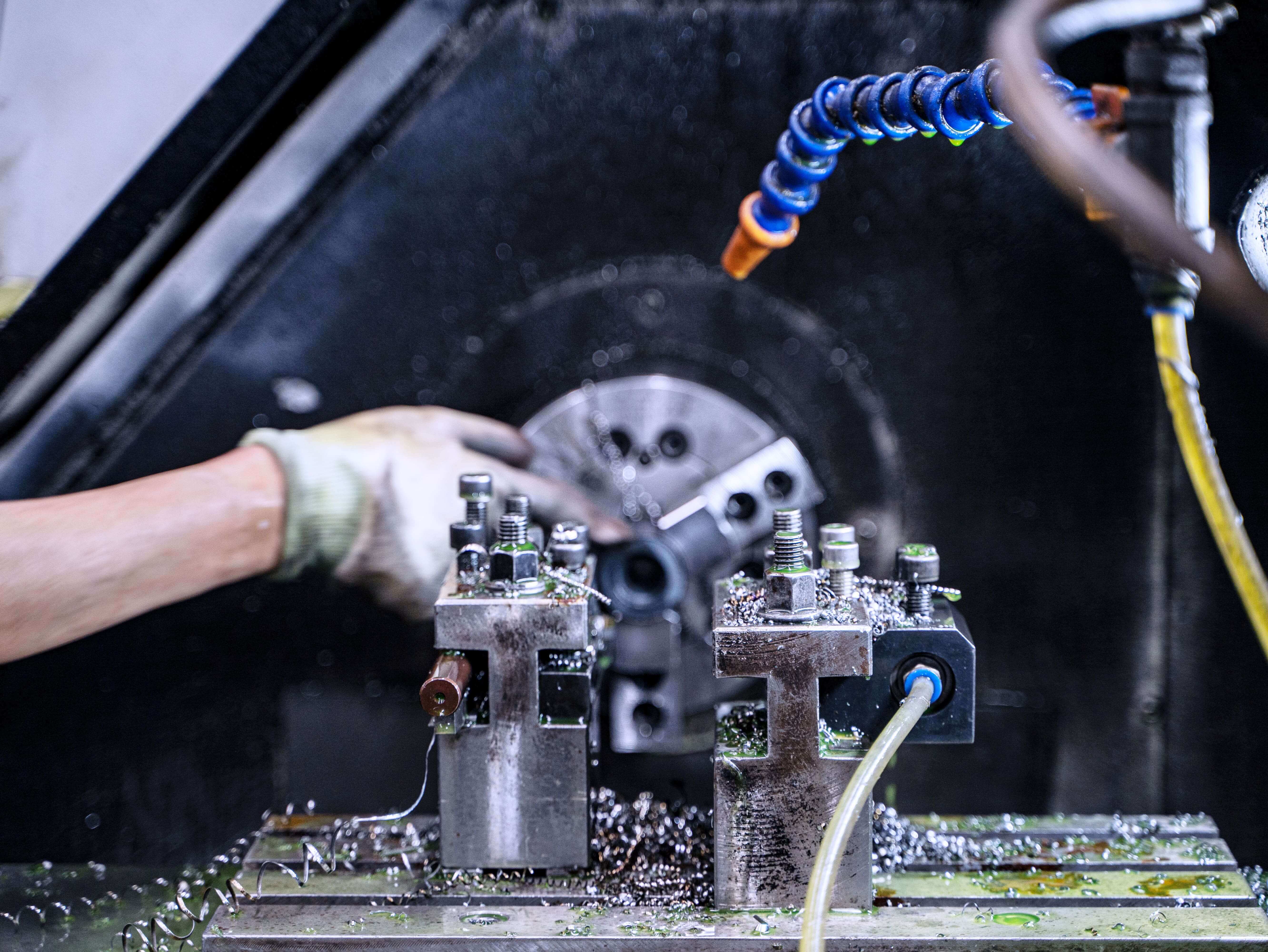

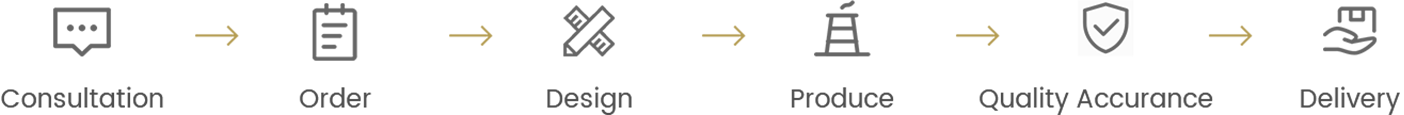

Processing

As manufacturers, we require every production step to adhere to the most stringent quality standards. With our advanced production facilities, years of industry expertise, and corresponding computing instruments, our production ensures furniture fasteners that fit perfectly according to given requirements. Our product performance ranges from class 4.8 to 12.9, with a diameter from 3mm-30mm and a length ranging from 6mm-300mm. Moreover, our product surface treatment methods include the use of blue-white zinc, colorful zinc, black zinc, military green zinc, oxidation, phosphating, trivalent chromium, dacromet, etc., to ensure their durability and can be customized according to one's demands.

Quality Control

We have always maintained a rigorous approach to product quality management, committed to meeting external requirements and expectations. Detailed inspections are carried out from initial proofing to series production. To meet the industry quality standards, CNRL will do a series of tests on furniture fasteners, including mechanical and chemical tests, such as hardness, metallographic, tensile strength, yield, neutral salt spray test, friction coefficient, etc., to ensure the quality and durability of all fasteners. The customized products will be assembled and tested on actual objects after production to ensure that the products delivered to customers meet the promise of exceeding their expectations! Consequently, our professional product inspection report is convenient for customers to check all the information regarding the QC of the product, offering them professional insight on the product quality. The packaging of the relevant accessories contains a description that provides essential installation information for different fasteners. Testing with the direct-reading spectrometer, plating thickness gauge, tensile testing machine, salt spray test chamber, Lowe's hardness tester, metallographic microscope, etc., helps conform to relevant industry standards as well.